GUADALAJARA TEST AND INSPECTION Is a qualified independent third party for inspection and testing company, we do product testing and certification services for more than ten years with a complete security laboratory, RF laboratory and chemical laboratory. Good for electrical test, test fixtures, chemical testing, toy testing, textile testing, reliability testing, performance testing and corrective measures to provide our customers a professional certification partner.

-

-

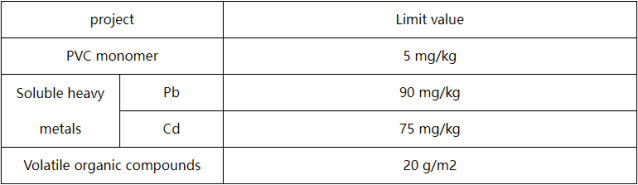

PVC limit of harmful substances

Introduction: this standard is a special standard for PVC artificial leather, which specifies the content control of harmful substances in PVC materials used in the production of domestic textile and leather products

Scope of application: PVC

Restrictions and requirements: mainly for three categories of hazardous substances, the specific requirements are as follows:

-

-

Leather limit of harmful substances

Brief introduction: this standard is for the compulsory limit of harmful substances in leather and fur products sold in China, and its nature is equivalent to GB 18401 standard in textiles

Scope of application: this standard is applicable to daily use leather and fur products, but not to industrial and special industry leather and fur products. The export products shall comply with the export contract or the provisions of the importing country. The following table is the classification of the controlled products in the standard

-

-

Toy Safety Test

With the development of society, the family care for infants and children is also more and more important, the development of the market for children care supplies is also accelerating, and the safety of children care supplies has attracted the attention of the whole society. At present, European and American and other countries and regions have set up special laws and standards to strictly control the safety of children care products in their market.

(1) Baby Pacifier - en1400

The European standard specifies the requirements for the material, structure, performance, packaging and label of baby pacifier.

1. general safety requirements

2. mechanical properties

3. chemical requirements and tests

3.1 migration of some elements

3.2 release of N-nitrosamines and N-nitroso

3.3 volatile matter content

3.4 MBT content in vulcanized rubber

3.5 release of antioxidants in vulcanized rubber

(2) Nipple Clip - en12586

The European standard specifies the following requirements for the manufacture of materials for drinking water equipment: Reusable feeding nipples and drinking water fittings; Reusable bottles and drinking cups, disposable bottles, feeding nipples, feeding bags, drinking water accessories, the above accessories do not contain liquid when purchased.

1. physical and mechanical properties

2. water resistance color fastness ISO 105-e01

3. color fastness to sweat ISO 105-e04

4. migration of specific elements

5. nickel release

6. colorant

7. formaldehyde

(3) Drinking equipment - en14350

The European standard specifies the requirements for materials, structures, properties, packaging and labeling of nursing and drinking appliances for infants and young children.

1. general mechanical properties

2. chemical requirements

2.1 migration of some elements

2.2 release of N-nitrosamines and N-nitroso

2.3 volatile matter content

2.4 bisphenol a release

2.5 MBT content in vulcanized rubber

2.6 release of antioxidants in vulcanized rubber

(4) Knives and forks and feeding appliances - en14372

The European standard specifies the requirements for materials, structures, properties, packaging and labeling of knives and forks and feeding appliances for infants and young children.

1. physical and mechanical properties

2. chemical requirements

2.1 migration of specific elements

2.2 phthalate content

2.3 bisphenol a release

2.4 nickel release

2.5 formaldehyde release

2.6 volatile matter content

(5) Baby bottle nipple - bs7368

The British standard specifies the requirements for the materials, structure, performance, packaging and labeling of bottle nipples for infants and young children.

1. physical and mechanical properties

2. volatile substance content

-

-

Inflatable Games Safety Test

Bouncy castles and inflatables need to be safe to use. With incidents having occurred in the past, there are strict regulations for ensuring the safety of inflatables.

Any new inflatable should have an initial test to confirm it complies with BS EN 14960. Every 12 months a bouncy castle or inflatable will need to be retested to ensure that it complies with BS EN 14960.

Broken down to its simplest, the test will comprise of the inspector:

- Identifying the inflatable and blower by their serial numbers.

- Checking any previous inspection reports and certificates.

- Inspectecting any part of the inflatable and its equipment that may affect its safe operation.

-

-

EU EN71

The European Union EN71 series of toy safety standards are a series of specific testing technical requirements and specifications formulated by Cen for toy safety directive 2009 / 48 / EC (formerly 88 / 378 / EEC). The EN 71 series standards cover all the indexes related to toy safety and environmental protection, and cover most kinds of toy products. All toy products sold in the EU need to meet the EN 71 testing standard.

Standard content

The items involved in EN 71 include the following 11 categories:

EN 71-1: physical and mechanical tests;

EN 71-2: flammability test;

EN 71-3: toxic metal migration test;

EN 71-4: chemical experiment toys;

EN 71-5: non experimental chemical toys;

EN 71-6: age warning label map;

EN 71-7: requirements for paints and coatings;

EN 71-8: rocking, sliding and similar toys for indoor and outdoor family entertainment;

EN 71-9: General requirements for organic compounds in toys;

EN 71-10: sample preparation and extraction of organic compounds;

EN 71-11: analytical methods for organic compounds;

-

-

Toy Safety Routine Test

In order to strengthen the supervision of the quality of children toys products and ensure the safety of children in the process of playing, all countries around the world are stepping up to establish and improve the quality and safety standards of toy products. At present, the conventional toy testing standards mainly include the technical specifications for toy safety in China GB6675, the European toy safety standard EN71, the American toy safety standard ASTM F963, the federal consumer goods safety act CPSC, the consumer goods safety improvement act CPSIA, the Canadian hazardous products (toys) Regulation c.r.c.c931, the Japanese toy safety standard ST2002 International safety standard iso8124 and other national standards.

(1) China Gb6675

This standard applies to all toys, i.e. all products and materials designed or intended for children under 14 to play.

1. mechanical and physical properties

1.1 normal use

1.2 foreseeable and reasonable abuse

1.3 materials

1.4 small parts

1.5 shape, scale and strength of certain toys

1.6 edge

1.7 tip

1.8 protrusions

1.9 wire and rod

1.10 plastic bags or plastic films used in packaging or toys

1.11 ropes and elastic ropes

1.12 folding mechanism

1.13 holes, gaps and accessibility in mechanical devices

1.14 spring

1.15 stability and load requirements

1.16 closed toys

1.17 imitation protective toys

1.18 ejection toys

1.19 water toys

1.20 brake device

1.21 toy bicycle

1.22 speed requirements for electric children's cars

1.23 heat source toys

1.24 liquid filled toys

1.25 mouth moving toys

1.26 toy roller skates and skateboards

1.27 toy gunpowder cap

1.28 similar simulation weapon toys

2. combustion performance

2.1 General requirements

2.2 whiskers, tentacles, wigs and masks and other headwear toys with hair or other accessories

2.3 makeup clothing

2.4 toys for children

2.5 soft fill toys

3. migration of specific elements

4. toy identification and instruction

(2) EU - En71

The toy directive is applicable to any product or material designed for or intended for play by children under 14 years of age.

1. mechanical and physical properties

1.1 General requirements

1.1.1 materials

1.1.2 assembly

1.1.3 flexible plastic film

1.1.4 toy bags

and more...

-

-

CPSA / CPSIA

Since CPSIA became the federal law of the United States on August 14, 2008, it has strictly defined the limits of toxic and harmful substances in children's products and toys. Now, before entering the U.S. market, all related products must pass the test of the third-party testing agency recognized by CPSC, otherwise they will face huge fines and lead to export interruption.

CPSA / CPSIA children's products / toys testing items include:

Lead content test of toys / children's products and coatings / paints

Test of small parts easy to cause suffocation

■ rubber / Pacifier

The above testing items are the most important testing items in the testing of toys / children's products, and almost all the testing of toys / children's products need to be tested.

-

-

Lead Detection

1. Introduction of total lead test

In recent years, in the recall cases of CPSC, lead content exceeded the standard frequently. Lead is widely used in a variety of daily consumer goods, such as toys, children's jewelry, packaging materials, food containers, ceramic products, furniture, stationery, metal accessories and so on, which is closely related to people's life. Excessive lead will have a significant impact on the human body and even the environment, such as the accumulation of high content in children's blood, which will affect children's IQ. In order to ensure human health and reduce the pollution caused by the accumulation of lead in the environment, countries around the world have promulgated corresponding regulations or standards to control the lead content in products at a safe level.

At present, according to the international standard, it is generally believed that the relative safety standard of blood lead should not exceed 10-14 μ g / L. Long term exposure to lead compounds or inhalation of metal lead dust can cause different degrees of "lead poisoning" (the serum lead concentration is more than 40 mg / 100ml) μ g) Excessive inhalation will harm the nervous system, heart and respiratory system, leading to lead poisoning in different degrees. Lead in the human body can combine with a variety of enzymes, thus interfering with various physiological activities of the organism, causing harm to the organs of the whole body. Children are far more likely to have lead poisoning than adults.2. Test limit of total lead content

1) According to the 2008 consumer product improvement act of CPSIA, ASTM F963 will become a mandatory standard after February 10, 2009, and the lead content limit in lead containing coatings will be reduced to 90ppm (although the requirement has been suspended by CPSC, the manufacturer is still obliged to meet the limit requirement);

2) According to a bill proposed by the Canadian government in June 2009, the limit of lead content in all consumer goods that may come into contact with the mouth (including the accessible parts designed for children under 3 years old) is changed from the current 600 ppm to 90 ppm;

3) According to CPSIA, the total lead content is limited to 600 ppm after February 10, 2009; After August 14, 2009, the total lead limit is 300ppm; After August 14, 2011, the total lead content was limited to 100 ppm.

3. We provide you with the following standard lead content test:

1)EPA3050B/30522)ASTM F963

3) Cal.65 (California 65) 16 CFR 1303

4)CPSIA H.R.4040

CPSA / CPSIA children's products / toys testing items include:

Lead content test of toys / children's products and coatings / paints

Test of small parts easy to cause suffocation

■ rubber / Pacifier

The above testing items are the most important testing items in the testing of toys / children's products, and almost all the testing of toys / children's products need to be tested.

CPSA / CPSIA children's products / toys testing items include:

Lead content test of toys / children's products and coatings / paints

Test of small parts easy to cause suffocation

■ rubber / Pacifier

The above testing items are the most important testing items in the testing of toys / children's products, and almost all the testing of toys / children's products need to be tested.